UDC Performance Factors

Factor 1: Increasing Strength

UDC strongly grips the abrasive grain on the carbon nanotube’s cutting edge and can prevent their separation. Moreover, UDC can increase the strength of tools and extend performance life.

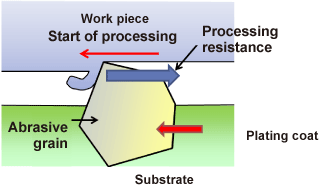

Conventional electrodeposition tool

Resistance from the work piece wears down the weak plating coat on a conventional electrodeposition tool, and it causes the abrasive grains to fall out. The loss of abrasive grains can cause the degradation of cutting performance.

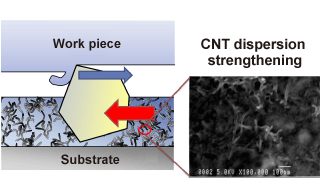

CNT composite electrodeposition tool

UDC increases the strength of the plating coat and prevents losses of abrasive grain on the cutting edge. UDC can increase the strength of tools and extend performance life.

日本語

日本語